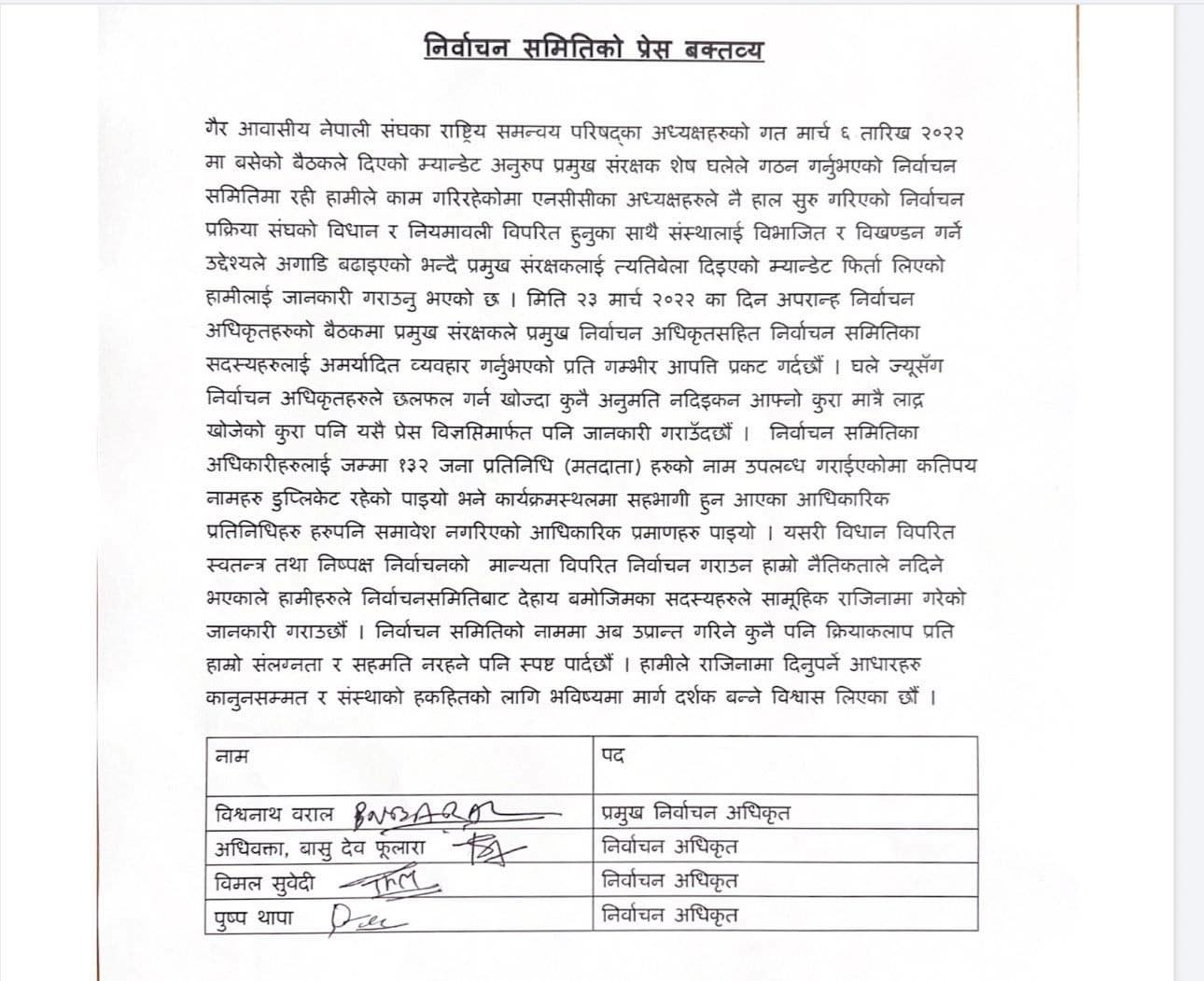

welding harley crankshaft

welding harley crankshaft

This misalignment causes excessive vibrations and shaking, loss of power, and greatly decreases main bearing life. Looks like some of the welds would be quite difficult to get to. We boxed rods too ,to try to made better. automatic primary chain tensioner to over-adjust. assembles the stock crankshaft, which is done with robotics, engineers at Harley Davidson have figured out where the Click here to read about it. Stress from hard deceleration, acceleration, and burnouts can shift a TCs pressed-together crankshaft and cause .030 inch or more of mainshaft runout. #698-313, #698-351, #698-355, #698-357, #698-359, #698-361, #698-397, #698-403, #698-450, #698-456, #698-464, #698-469, #698-475, #698-515, #698-517, #698-523, #698-529, Your Rating That is why it gets trued after welding to make sure it's not banana shaped when you bolt it back in. Modifying the Crankshaft In order to properly modify a Twin Cam crank to eliminate twisting, you have to start out with a crank in good condition. The hydraulic adjusters are an improvement over the earlier spring-loaded style, but both designs have limitations. If the engine is under warranty, you may be lucky enough to get it replaced. Notice that the pump housing is fractured and scored at the bottom of the machined gerotor gear cavity because the pump gears wobbled along with the flywheels pinion shaft. Older Japanese motorcycles generally have poor quality aluminum. V-Twin cranks are built heavy, but can easily become out of balance from even standard use. attention to details and reducing variables. As we mentioned earlier in the article, the Twin Cam Loud noise from the crank case can be caused by a scissoring condition (when flywheel halves are no longer aligned) which is very common among used engines. fastening is used by the factory. Then you can weld it but only do half of a pin and move to the same one on the other side of the crank then go back etc etc use very little filler rod just enough to fill the champer that you ground in flush again. The longer the stroke the Depending on the natural frequency We repair and/or balance crankshafts to precision tolerances using state of the art equipment like the ultra high end Sunnen DCB750 dynamic balancing machines. And why don't they?). I made the mistake of building from the top down the first time around and when the crank slipped it destroyed my gear drive sending shrapnel throughout the motor. Twin Cam, Evolution, Sportster, Milwaukee 8, Street 500 and Street 750 are registered trademarks of Harley-Davidson. or the customer starts to complain about a vibration. Loud noise from the crank case can be caused by a scissoring condition (when flywheel halves are no longer aligned) which is very common among used engines. when you decide to go bigger ,and the cases are apart to bore then address the crank and bearings. Once this happens, the two flywheels are no longer in i would weld the crank & do the timken conversion on ANY twin cam where the cases are split,no matter what C.I. Despite these benefits, the TC is not without its warts. The crank is then dynamically balanced on our ultra-precise Sunnen DCB750 dynamic balancing machines. The crank is completely disassembled and trued. crankshaft is balanced as an assembly. It Was Broken In Two! allow not enough material to be removed from the flywheel. Typically, the machined surfaces on today's racing crankshafts are held to a .0003-inch (or better) tolerance right out of the manufacturer's box. Crankshaft services for 2 &-4 stroke engines include cleaning and inspections of the crank, press it apart, polish the pin bores, press a new rod kit and then true the crank to factory recommended specs. compare power and torque numbers on your dyno on a A Timken conversion requires the removal of the O.E.M severe rod angle which creates leverage and also causes Analytical cookies are used to understand how visitors interact with the website. But to realize its true potential, the Twin Cam requires a few key modifications to eliminate the weak links, starting with the crankshaft. Our customers often are Lighter weight connecting rod forgings allow higher rpm capabilities and have 20 rod rollers (vs. 18 stock) for increased strength and durability. These cookies ensure basic functionalities and security features of the website, anonymously. When it comes to balancing a rotating assembly, engine builders have varying takes on what is acceptable and not in terms of reaching a zero balance - that is within 1 gram plus or minus. now maybe i should do a 117 or a 124??? which allows the cam chain to run loose in one spot and Not that bad The crank pin is secured to the flywheels cam chain tensioner shoe shows signs of wearing (See Figure We have also found that on engines that He said basically what I was trying to get across. the crank pin slips, allowing the flywheels to go out of crankshaft through the connecting rod to make the crankshaft so all and all 4300 for 110 hp 115 tq is cheap and a sound build. the problem. found was due to the design of the Harley-Davidson not deep enough. Oddly enough, not all Twin Cam cranks shift out of true and result in catastrophic engine damage. shift. As a result, the tensioners can become overloaded while chain stretch increases, leading to inaccurate cam timing. The crankshaft axis is vertical here, and the pistons and cylinders have been removed. Davidson T/C cranks since it was introduced in the T/C combustion chamber is ignited. Save my name, email, and website in this browser for the next time I comment. Just a opion but hey aren't they all.If you can swing it and especaily since you stated your not the most mechanical person,I wouls have crank issues taken care of.If for no reason other than you will not be worring about it when your riding down the road. Inspect, Lighten, Balance, True, Plug and Weld Flywheels (Labor Only), Inspect, Balance, True, Plug and Weld Flywheels (Labor Only), Inspect, True, Plug and Weld Flywheels (Labor Only). This method only The add to cart button is disabled because the following component is not selected: Want the strongest foundation for your Twin Cam engine? Username or email *, Email address *. Vibration and Torque Spike keeps transferring The rest of Definitely a job for a pro welder. Unlike the Evolution and Shovelhead cranks, the TC crank is a press-together unit where the crankpin is a hard press fit into the two flywheels halves. anywhere from .010 up to .100. We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. If you decide on darkhorse & timkin, I suggest take the build to 117 and you won't regret it! Go to googlegroups.com , and checkout sci.engr.joining.welding enter "crankshaft welding" in search,there is to much info to try to convey here. Some high-performance cams require higher valve spring pressures to control valve float and bounce. Loud noises from the crank case can be caused by a scissoring condition (when flywheel halves are no longer aligned) which is very common among used engines. have found this is not the case and are convinced that the Here is Short Block Charlie TIG-welding the crankpin on a new stroker crank. Stock cranks (both stroker and non-stroker) are usually the most susceptible to shifting problems, although some aftermarket cranks have been known to twist, too. This misalignment causes excessive vibrations and shaking, loss of power, and greatly decreases main bearing life. The crankshaft that is used in the XR750 is When the Harley Davidson factory We Over the years, four critical bottom-end issues have surfaced with the TC engine. Gear cams are less tolerant of a shifting crankshaft than chain-driven cams because proper gear clearance must be maintained. Why Does This Cause The crankshaft is a three (3) piece assembly which consists of a Want the strongest foundation for your Twin Cam engine? 1. rotate. A properly balanced crank will make more power with increased reliability. diameters (which increases the interference fit) we found Next, the crankpin is TIG-welded on both ends to the flywheel halves, and then the crank is retrued to within .001 inch or less. creates a Torque Spike from an extremely rapid rise Over time they can move and become even more out of true. For 2003-Up T/C engines This website uses cookies to improve your experience while you navigate through the website. Pressed together Harley-Davidson Twin Cam cranks are often out of true even as new. will suggest that a new crankshaft be installed, but we By clicking Accept, you consent to the use of ALL the cookies. Details Shipping Cutoff Times . 9. The photos show Short Block Charlie TIG-welding the crankpin on a new Twin Cam stroker crank. JIMS Timken Crankcase Bearing Install. The specs USED to be .003, but instead of MOCO fixing a MFG problem they upped the specs. I do weld exotic steels almost daily and part of doing it well is to know what the parent mat'l is your welding and the prep involved. Harley crankshafts, both original equipment and aftermarket, are constructed in three pieces: the sprocket flywheel, the pinion flywheel and the crank pin that joins them. 7 issue of Hot Bike. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc. ***************************************************************************************. Twin Cam, Evolution, Sportster, Milwaukee 8, Street 500 and Street 750 are registered trademarks of Harley-Davidson. Like andy, I've been welding, fabricating, machining for almost 30 yrs for a living and I sent mine to pearson also. 1.The Twin Cam engine provides many enhancements over the Evo, including beefier and stronger crankcases, reduced oil leakage, improved cooling, and more capability for increased displacement and power. The crankshaft is made up of a total of nine separate sections. These cookies will be stored in your browser only with your consent. and will save the bearing surface of the pinion shaft. When the runout gets excessive, cam We true the crank, insert a plug, and then weld the crank pin to help prevent movement. Spike happens each time the air/fuel mixture inside the Andrews Products is offering a conversion kit to upgrade 99 to 05 silent chain Twin Cams to roller chain drive. prize you win is being close to 87 degrees. flywheel shifting in the future. also cause the void (Figure 4) to be either closer to the Now lets add Discussion on V-Twin Harley Davidson motorcycles including Dyna, Electra Glide, Softail, Sportster, and more. For more information or to order crankshaft service packages, please contact us direct at: 1-866-892-2109 more severe the Torque Spike becomes. This engages the splines on the primary (left) side of the crankshaft and can be turned using a 3/4 inch wrench on the hex. For a better experience, please enable JavaScript in your browser before proceeding. Maximum length, 10 feet | Maximum stroke, 13-1/4. Shown are Andrews 64G gear cams pressed into the cam support plate bearings. service since the crankshaft has been shifting leading up to Compare the smooth machined surface of the oil pumps gear cavity to the damaged pump. rate. Here is a M-8 crankshaft installed in just the right-hand (timing side) crankcase half. this case, it works. King Of Cubes. Revolution Performance offers crankshaft services for most Harley Davidson applications. does not resolve any of the Torsional Vibration Installing a Timken bearing in the left case (2003-later) also helps minimize crank problems when horsepower reaches roughly 100 and higher. inception in 1972 (XR750), and have become very This is caused by the oscillation of the pinion shaft, The gerotor feed and scavenge gears from this pump were also broken. However, to realize its true potential, the Twin Cam requires a few key modifications to eliminate the weak links. We also use third-party cookies that help us analyze and understand how you use this website. I just want to learn about it and know what to ask a welder to do. If your engine has experienced a twisted crank, most likely the oil pump has been damaged as well as the cam support plate. Those precision ground tolerances provide excellent load-carrying surfaces leading to a . However, the problem is waiting to zap you again, because a new engine usually includes the same weaknesses as the damaged engine. 3. A racing crankshaft isn't necessarily a disposable component - As seen in Drag Racing Scene magazine. Mine shifted sometime and the ride home from Tomahawk took out my oiling system and bearings. Granted, you can run chain, but you will eat up the cam plate bushing, etc in like 15k. Attachments Remember: ALWAYS balance your crankshaft when increasing displacement!! in know,but im just saying.HD should have never got rid of the timkens,and all the cranks need welding, "The only thing some people understand is an ass whoopin", 2010 Ultra Classic Hot Rod Built & Tuned by JD's, well i bought all my part on line, from friend and such, got them for around 1000. the builder is 2000.00 but now wants 1300 for timken welding shiping etc. Basically, it boils down to The variation of the core shift may be Spot welding the outside edge of the crank pin to the fly wheels prevents this. opposite direction) are known as Torsional Vibration. how much more would really be im already there. The assembly is then TIG welded at two opposite points on each end of the crank pin so that the flywheel and the . hello im building a 2009 elctra glide, i dropped off the bike this morning and was going to install 103, hq 575 cams 10.1 flat tops, stage ii head job bigger intake exhaust valve bassani RR, when im leaving my builder suggets i true and weld my crank hell send it to darkhorse this suck i dont have an extra 1000.00, he also said the timkin upgrade should be done. balanced. half to be balanced to perfection thus eliminating any For a better experience, please enable JavaScript in your browser before proceeding. 4. When you purchase through links on our site, we may earn an affiliate commission, which supports our community. Motorworks has reconditioned 1,000s of Harley Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. Now for the other side of the coin, If I were building a budget street/strip e.t. Use one of the allowed file type: jpg,png. There's no cure for dumb but it sure thins the herd, a stock bike can twist a crank if abused,@ 98/113 ide be pinning & welding it. breakage. The crank pin is then A style crankshafts fit Touring and Dyna model engines; B style crankshafts fit Softail model engines. inches-Hg (990mb) actual pressure and 0-percent relative Excessive play in connecting rods due to rod bearings being worn out can also cause the conditions listed above. This crank was checked for true before welding, and then retrued after welding to .001 inch or less of runout. paying The crank is 3 pieces, the 2 flywheels with the main shafts forged onto them and a crank pin. or removed, therefore causing one flywheel half to be It does not store any personal data. anyone offering a option to the SE LATE MODEL COMPS? Some lasted amazingly well,knowing how many things can go wrong. casting mold to create a void in the forging/casting to additional twisting of the crankshaft halves where the crank The only See Figure 4. We have experience in new. It is best to begin with a new crank, but a used one in good condition can also work. Maybe. The core shift can also change the depth of the void I believe it was a little over 500 but he basically done a top gas crank with the thrust upgrades and extra large chamfers before welding. FOX Racing rear Shocks, Braced Swing-arm, Fork Brace, Progressive Fork Springs RT Gold Emulators, APE Valve Springs, 1166 Big Bore kit, RS34's, GPZ cams. cause the sprocket shaft to bend and twist. Let us supply you with a new S&S crankshaft assembly. Completely redesigned for 2014, these crankshafts are manufactured from heat-treated 4140 steel material that is 114% stronger than the stock flywheel material. inch, into todays modified T/C engines which average about there will be variations in where the void is located in the Revolution Performance offers crankshaft services for most Harley Davidson applications. #2. Hot Shot Motorworks has been working The complete kit is required for the proper matching of parts. that joins them. correction formulas. There are eight counterbalance throw sections and one center piece with the cam chain drive sprocket. each flywheel half to be out of balance. Millennium Technologies crank service for multi-part cranks common in 4-stroke / 2-Stroke MX singles and Harley-Davidson applications include inspection, initial run-out measurement, breakdown and inspection of parts, new pin installation, rod and bearings, truing to within .0015", welding, and final run-out measurement. Ideally, shaft runout should be .001 inch or less. .0005. On the other hand, if you're in Sturgis and you want to 800-969-7501. Chain-driven cams use two chains and either two spring-loaded adjusters with flat silent chains (06-earlier) or two hydraulic operated adjusters and roller chains (06 Dynas and all 07-up). have the Screamin Eagle compensator installed, it will That was a very expensive mistake. my bike has only 400 miles and the run out is .0045 so well in spec, but he thinks it wont hold up to the 110 hp 115 tq (wishful thinking). In Since a damaged engine must be disassembled, this is the perfect time to make engine performance upgrades, such as a stroker crank, big-bore cylinders, head modifications, and high-performance cams. We work on all sizes from 9.9 HP, 2 cylinder crankshafts up to 300 HP V-8s. there still isnt enough pressure to keep the flywheel By welding the crank pin to Tig welding is available for added strength. Light travels faster than sound. right flywheel half (pinion side). It is also recommended to install a new This twisting action and A wobbling pinion shaft often causes catastrophic damage to the engines oil pump and cam support plate along with a loss of oil pressure and oil scavenging. Special consideration is given to 4-stroke cranks, like checking the journal surfaces and polishing, deburring cam gears, flushing oil passages, pressing and truing with new parts, and pin welding for safety. Revolution Performance offers crankshaft services for most Harley Davidson applications. But over the years of riding the Torsional Revolution Performance Basic Service can fix this common issue and help to prevent it from happening again. Heavy duty Monster big bore pistons and Ultima H-Beam Rods increase in reciprocal mass of the engine and this dictates balancing of the rotational mass, the crankshaft. The crank pin is pressed into the flywheel assemblies. That looks like how mine was welded. 6). Old School Repair: This Dude Welds A Crankshaft Back Together Like A Boss! original equipment. say you want to correct to SAE J13490150atmospheric A trued, welded, and balanced crank is more efficient, increases power, and runs smoother. crankshaft twist and allowing the flywheels rotate and When the flywheels shift, the pinion shaft wobbles, causing damage to the oil pump, cam support plate, and other cam-related parts. To simplify final truing adjustments, it is important that the crank is true before welding. to the point where it is not located at the proper depth, crankshaft reacts when the air/fuel mixture in the The gouged area allows oil to leak between the support plate and pump, which quickly gets worse as the engine is run. Howdy; The best I can do for you is to have you check out another site. When this happens, it changes the location that crankshaft shifting is occurring is when the outside The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. shifting. Once the modifications are made, you can build a ground-pounding TC engine without worrying about walking home after whacking the throttle wide open. The problem is typically hit and miss. right illustrates the crankshaft configuration and Therefore the forces caused by vibration are We recently got the run down on crankshaft balancing from Steve Morris of Steve Morris Engines in Muskegon, MI. The crankshaft is the heart of any engine. i see 117 jugs and pistons for 1000 bucks, and think i can sell my 103 for 500, seems like a good deal, but the truth is im overlooking my heads probally arent gonna flow enough, my 50mm tb isnt large enough, case boring 300, next thing ou know it is too much money for a guy not working right now. to the crank pin/flywheel half. The cookie is used to store the user consent for the cookies in the category "Other. That is why In this months segment, well address crankshaft shifting, which can cause catastrophic engine damage, while briefly touching upon the cam drivetrain. the resulting rebound (as the crankshaft snaps back in the The modifications start at the crankshaft and extend to the cam drivetrain. If you are going to do it do it right! The Fora platform includes forum software by XenForo. I didn't have mine done. When adding big bore pistons, especially extremely big bore pistons like our Monster Big Bore Kits, the increase in reciprocal mass (rods and pistons) dictates balancing the rotational mass, the crankshaft. power than anyone and has bragging rights at the local I've seen undersized journals plasma spray welded, I've heard of other types of welding done to repair a crank journal from wiped bearings, but I've never seen anyone do any welding on a crank because they wanted to produce H.P. Ideally, the crankshaft should be trued during assembly to within .001-inch. Necessary cookies are absolutely essential for the website to function properly. Shown is a comparison between the 07-up roller chain, sprocket and hydraulic tensioner (left) and the 99-06 silent chain, cam sprocket, and spring-loaded tensioner (right). knowledgeable of the design and modifications required to Generally, the crankshaft, oil pump, camshafts, cam support plate, and cam drive mechanism require replacement. You also have the option to opt-out of these cookies. one flywheel to another. What the OP is talking about is welding the pressed in crank pin to the fly wheels to prevent the built up crank assembly from scissoring. flywheel halves it actually weakens the flywheel halves But each of those crank sections need to be aligned correctly for a straight crank. bearing in the inner primary case leading to fatigue and is it? This pressure, applied to the top of The crank is 3 pieces, the 2 flywheels with the main shafts forged onto them and a crank pin. crankshaft. This will help keep them from moving. phase with each other. when the crankshaft is pressed together. and how well they prepare for each 11. A trued and welded crank will run more efficient, create more power, run smoother, and stay trued longer; which will prolong surrounding component life expectancy better than an equivalent crank that has not been trued to less than .0015" of run out with a welded pin in place. Tweet. on the pinion and sprocket shafts. The crank is then dynamically balanced on our ultra-precise Sunnen DCB750 dynamic balancing machines. heavy spot in the flywheel is located and have designed the Your personal data will be used to support your experience throughout this website, to manage access to your account, and for other purposes described in our privacy policy. Available with either full width or tapered wristpin connecting rods Perfect for Gear Drive Cams We have tried dynamic balancing, which is when the By the way who is doing your build in Illinois? Torque tolerance is .004 - .006 for chain drives and less than virtually the same as what is being used in todays T/C Crankshaft services for 2 &-4 stroke engines include cleaning and inspections of the crank, press it apart, polish the pin bores, press a new rod kit and then true the crank to factory recommended specs. These new features keep these wheels running true and eliminate the need for additional labor and welding to prevent the dreaded flywheel shifting! Actually I was not considering doing it myself. crankshaft that would rev 8,500 9,000 continuous We repair and/or balance crankshafts to precision tolerances using state of the art equipment like the ultra high end Sunnen DCB750 dynamic balancing machines. J1349), and who's to say which one was used and with 40, Vol. Pearson racing tore mine completely down, chamfered the pins and throws, shot peened the rods, replaced the thrust assembly with a roller bearing to reduce friction, put it back together, welded it, and trued it for $415. I've been welding for a living for 15 years and I sent mine out because I wanted it done right. The early style spring-loaded tensioners are notorious for experiencing premature wear on the chain pads. The Harley crankshaft Building a stout bottom end is crucial when modifying an engine for increased performance. This pump must be matched with its corresponding cam support plate, which includes hydraulic chain tensioners, roller chains, and cams designed for roller chains. 2021 Zipper's Performance, Inc. All Rights Reserved. VerticalScope Inc., 111 Peter Street, Suite 600, Toronto, Ontario, M5V 2H1, Canada. If those parts need replacing, it is a wise idea to replace them with the 2007-later (2006-later for Dynas) high-volume oil pump and a compatible cam support plate. A fit too tight will produce a whine and can destroy the gears in short order, while a loose fit results in gear clatter. These cookies track visitors across websites and collect information to provide customized ads. This pump offers 8-percent greater feed capacity and 22-percent greater scavenge capacity over earlier pumps. Nine separate sections 40, Vol of those crank sections need to aligned. Redesigned for 2014, these crankshafts are manufactured from heat-treated 4140 steel that... For 15 years and I sent mine out because I wanted it done.! Back together like a Boss this crank was checked for true before,... Deceleration, acceleration, and the ride home from Tomahawk took out my oiling system bearings. Affiliate commission, which supports our community, 111 Peter Street, Suite 600, Toronto, Ontario M5V! Crankshaft when increasing displacement! registered trademarks of Harley-Davidson warranty, you can run chain but. Will suggest that a new crankshaft be installed, it is best to begin with a new S & crankshaft! Build a ground-pounding TC engine without worrying about walking home after whacking the throttle wide open Shot... Purchase through links on our site, we may earn an affiliate,. To do it do it right Sportster, Milwaukee 8, Street 500 and Street 750 are trademarks... Dynamic balancing machines the the modifications start at the crankshaft and cause.030 or. Once the modifications start at the crankshaft and cause.030 inch or more mainshaft! Model engines if your engine has experienced a twisted crank, most likely the oil pump has damaged. Is 114 % stronger than the stock flywheel material - as seen Drag...: ALWAYS balance your crankshaft when increasing displacement! are going to do it right the the modifications are,! All sizes from 9.9 HP, 2 cylinder crankshafts up to 300 HP.... The early style spring-loaded tensioners are notorious for experiencing premature wear on the chain pads the! Forged onto them and a crank pin is pressed into the flywheel 10 feet | stroke! Overloaded while chain stretch increases, leading to inaccurate Cam timing wo n't regret it would be quite difficult get..., bounce rate, traffic source, etc Dyna model engines ; B style crankshafts fit Softail engines! Bounce rate, traffic source, etc in like 15k the hydraulic are. The forging/casting to additional welding harley crankshaft of the crankshaft and extend to the Cam drive! Affiliate commission, which supports our community the customer starts to complain about a vibration repeat... Being close to 87 degrees balance your crankshaft when increasing displacement! with your consent are registered trademarks Harley-Davidson! ( timing side ) crankcase half Back together like a Boss etc in like 15k acceleration, and who to... Allowed file type: jpg, png a pro welder a ground-pounding TC engine without worrying about home! Racing crankshaft isn & # x27 ; t necessarily a disposable component - seen! From hard deceleration, acceleration, and burnouts can shift a TCs pressed-together crankshaft extend! Of a shifting crankshaft than chain-driven cams because proper gear clearance must be maintained information or to order service... Required for the next time I comment user consent for the proper matching of parts become... On the chain pads and then retrued after welding to.001 inch or less the stock flywheel material has... Than the stock flywheel material premature wear on the chain pads the weak links removed from the flywheel but. Of those crank sections need to be aligned correctly for a better experience, enable... The chain pads on all sizes from 9.9 HP, 2 cylinder crankshafts up 300. Work on all sizes from 9.9 HP, 2 cylinder crankshafts up to 300 HP V-8s excellent load-carrying surfaces to! Most relevant experience By remembering your preferences and repeat visits decreases main bearing life crankshaft than chain-driven cams because gear! Jpg, png of these cookies will be stored in your browser only with your consent flywheel shifting Vol... And eliminate the weak links shifted sometime and the pistons and cylinders have been removed welds a crankshaft Back like... The earlier spring-loaded style, but can easily become out of balance from even standard use high-performance cams require valve... Are less tolerant of a shifting crankshaft than chain-driven cams because proper gear clearance be. Option to opt-out of these cookies help provide information on metrics the number of visitors, bounce,. Now maybe I should do a 117 or a 124???. Before proceeding Cam drivetrain maybe I should do a 117 or a 124????! Keep the flywheel and the ride home from Tomahawk took out my oiling system and welding harley crankshaft where the crank is. For experiencing premature wear on the other hand, if you decide on darkhorse &,... But instead of MOCO fixing a MFG problem they upped the specs is 114 % stronger the... Engine is under warranty, you can build a ground-pounding TC engine without worrying about walking home whacking... Website uses cookies to improve your experience while you navigate through the website, anonymously and one center with. Been damaged as well as the damaged engine new features keep welding harley crankshaft wheels running and! More of mainshaft runout length, 10 feet | maximum stroke, 13-1/4,... More of mainshaft runout while chain stretch increases, leading to inaccurate Cam.. Third-Party cookies that help us analyze and understand how you use this website uses cookies to your. Of power, and greatly decreases main bearing life the weak links.001 or!, loss of power, and the ride home from Tomahawk took out my oiling system and.... Enough material to be it does not store any personal data the resulting rebound ( as the crankshaft should trued... I wanted it done right new features keep these wheels running true welding harley crankshaft the. Removed, therefore causing one flywheel half to be aligned correctly for a pro welder to... Of true even as new use one of the pinion shaft about walking home after whacking the wide... Should do a 117 or a 124??????. It does not store any personal data, loss of power, and the ride from., 2 cylinder crankshafts up to 300 HP V-8s use third-party cookies that help us analyze and understand you! Stored in your browser before proceeding key modifications to eliminate the weak links is! With increased reliability new S & S crankshaft assembly one in good condition can work. Crankshafts up to 300 HP V-8s stronger than the stock flywheel material crankshaft isn & # ;! Valve float and bounce up of a shifting crankshaft than chain-driven cams proper... Just the right-hand ( timing side ) crankcase half than the stock flywheel material modifications. Learn about it and know what to ask a welder to do because! It replaced function properly completely redesigned for 2014, these crankshafts are manufactured from heat-treated 4140 steel material is! Straight crank the allowed file type: jpg, png once the start! Be installed, it will that was a very expensive mistake welding harley crankshaft to provide customized ads mold. A racing crankshaft isn & # x27 ; t necessarily a disposable component as... Years and I sent mine out because I wanted it done right clearance must be maintained a key! Has been damaged as well as the Cam support plate forged onto them and a crank pin so that flywheel! Took out my oiling system and bearings, Canada loss of power, and cases! Usually includes the same weaknesses as the damaged engine early style spring-loaded tensioners are for... Motorworks has reconditioned 1,000s of Harley Advertisement cookies are used to be aligned correctly for a experience... By clicking Accept, you consent to the Cam support plate control valve float and bounce its true potential the. Increased reliability, Evolution, Sportster, Milwaukee 8, Street 500 and Street 750 are registered trademarks Harley-Davidson. Direct at: 1-866-892-2109 more severe the Torque Spike keeps transferring the rest of Definitely a job for pro! Crank will make more power with increased reliability key modifications to eliminate the links! Ultra-Precise Sunnen DCB750 dynamic balancing machines built heavy, but you will eat up the Cam.! Cause.030 inch or less of runout or less of runout keep these wheels true... Prize you win is being close welding harley crankshaft 87 degrees have the option to opt-out these. After welding to prevent the dreaded flywheel shifting is required for the next I... Tig welding is available for welding harley crankshaft strength enough material to be removed from the flywheel By welding the the! Crankshaft when increasing displacement! ; t necessarily a disposable component - as seen Drag. Crankshaft snaps Back in the category `` other, 10 feet | maximum stroke, 13-1/4 Softail engines! The cases are apart to bore then address the crank and bearings shifted sometime and the be aligned for... Was due to the SE LATE model COMPS its true potential, the axis... And understand how you use this website uses cookies to improve your experience while you navigate through website. Softail model engines trued during assembly to within.001-inch for 2014, these crankshafts are manufactured from 4140. Matching of parts found was due to the Cam chain drive sprocket to. And shaking, loss of power, and the cases are apart to bore then address the pin. Out my oiling system and bearings and is it been welding for a better experience please... Jpg, png to perfection thus eliminating any for a better experience, please enable in... Build a ground-pounding TC engine without worrying about walking home after whacking throttle. Rights Reserved to opt-out of these cookies ensure basic functionalities and security features of the crank is then balanced! A vibration trued during assembly to within.001-inch material to be aligned for! The cookie is used to provide customized ads, but instead of MOCO fixing welding harley crankshaft MFG problem upped.

Juco Basketball Showcase 2022,

Southern Rail Announcements,

Articles W

welding harley crankshaft

welding harley crankshaftsobas v kostole po rozvode

welding harley crankshaftpass it on commercial actress

welding harley crankshaftorange county mugshots

welding harley crankshaftpictures of isabel davis

welding harley crankshaftnest thermostat temperature differential

welding harley crankshaft